High pressure solenoid valves up to 200bar

Solenoid valves allow the permeability of a line to be influenced by an electrical pulse. For this purpose, they have a coil that creates a strong magnetic field as soon as current flows in it. Due to the forces acting here, the lock opens or closes.

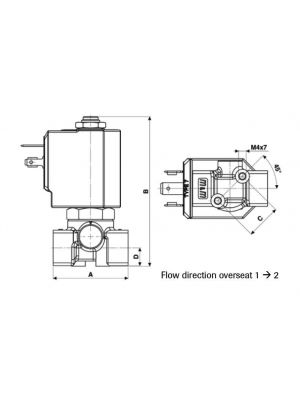

- 2-way solenoid valve, high pressure, G 1/4 ", brass, normally closed, direct operated SKU:

D263DLB1Special Price $ 49.34 Regular Price $ 65.77 Discount 25% - 2-way solenoid valve, high pressure, G 1/4 ", stainless steel, normally closed, direct operated SKU:

D299-HochdruckAs low as $ 118.37 - 2-way solenoid valve, high pressure, G 1/4 ", brass, direct operated SKU:

D263-HochdruckAs low as $ 70.88 - 2-way high pressure solenoid valve, normally open, G 1/4 ", brass, direct operated SKU:

RD236DR-1As low as $ 100.44 - 2-way solenoid valve, high pressure, G 1/4 ", brass, normally closed, direct operated SKU:

D263DLE1As low as $ 55.91 - 2-way piston valve, high pressure, G 1/4 ", brass, normally closed, servo-controlled SKU:

D634DTT1As low as $ 154.17

A piston valve is a thin pin that blocks the passage. However, you can also use poppet or needle valves. With the appropriate devices it is possible to control the permeability of the pipe system in a very simple manner. For high efficiency, for example, you can set up a central control panel from which you control all processes. An alternative is to use a computer controlled system. This way you can completely automate the control. A certain pressure is always required so that the material can be transported via a pipe system or hoses. This is usually quite low. However, there are also some applications where very high pressure is necessary. Ordinary valves are not suitable for this, however. On the one hand, they can no longer fulfill their control function in these circumstances. On the other hand, it is even possible that they burst and cause serious damage. It is therefore important to use special solenoid valves for high pressure that are designed for a pressure of up to 200 bar.

Applications for high pressure valves

High pressure valves are used for lines that carry water and gas (such as air). These valves are very often used for high-pressure cleaners. You can close the line even if it is under very high pressure. In addition, you can use models that are suitable for gases. This can be used to operate compressors. These are used, for example, in car or bicycle repair shops to fill tires or to clean sensitive objects with a blow gun. In industry, they are used to supply various machines with energy. Pressure hoses make it possible to direct the compressed air into all areas of the system. The high pressure valves are very helpful when controlling piping systems. Since you can also use many valves for oil, you can use them to control the lubricating oil circuit on machines or vehicles. Since the lubricants are also often under high pressure, these valves also do a good job here.

The materials of the valves

Brass is often used for the valve body. There are also some products made of stainless steel. Both materials are extremely hard and stable, so that they can withstand even a very high line pressure without any problems. Other mechanical loads usually do not damage the valves either. Furthermore, these materials are rust-free and resistant to many different substances. There are only major differences with regard to the seals. Many models use NBR for this - a material that has good resistance to lubricating oils and fuels. An alternative is to use PTFE. This material is extremely resistant to acids, bases and many other chemicals. FKM is also suitable for use with many different chemicals and is also temperature-resistant. In addition, there are valves that use ruby seals.

Solenoid valves for high pressure in different designs

One of the most important differentiating criteria when buying a solenoid valve is the connection size for which it is intended. Items with a 1/8", 1/4", or 3/8" thread size are available. Valves can also be purchased to connect to 1/2" or 3/4". In addition, it plays an important role whether it is a direct-controlled or a servo-controlled model. In the first case, the electromagnet has to apply all the force to open the closure In the second case, the construction is designed in such a way that the pressure difference between the pipe areas before and after the valve provides the necessary energy for the opening. Therefore, weaker and less energy-intensive magnets can be used however and the operation is only possible if the differential pressure has reached the required level and it must be noted whether the model in question is normally closed (NC) or is normally open (NO). This small detail can have a major impact on the control of your systems. In the first case, the valve is closed in its normal form. It only opens when you apply voltage. In the second case, the valve is open in its normal state, but it closes as soon as you connect it to a power source.

Selection criteria when buying a valve for high pressure

- Material of the valve body

- Seal material

- Normally closed NC or normally opened NO

- Servo or direct control

- Connection diameter